Given a normal bit of desk or rack mounted 12v powered equipment, fitting a simple fused changeover relay would take me around 5min, and that includes working out the wiring route and tying it into the loom.

Exactly the same task, but on my car? Well, after 2 hours I'd found somewhere to mount the relay, and got the control wire through the bulkhead! and thats with the wire running parallel with the already routed bloody thick high current cable for the transceiver!

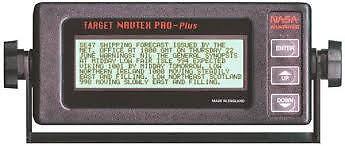

The purpose of this relay is to kill power to the transceiver when the ignition is off. As it currently stands, I can easily leave the radio on without noticing, with the result that I go to set off for work after 4-5 days off, and the battery is flat!

So, a 30A relay and a suitable tap into the switched supplies is needed. A few quid. But far more hassle! First of course, I had to find a suitable switched supply! The dashcams are fed from the switched feed to the wiper motor controller, which being an 'add-a-circuit' type piggy-back fuse holder connection, actually covers up several fuse positions! Luckily, Ive found that F44, a 3A feed to the cars audio system, is accessible. An extra 100mA or so on this wont hurt, and it keeps all the audio/comms systems on the same main circuits.

Then, where to mount the relay? This needs to be close to the battery, but of course cannot be on it! The nearest available secure place I could find was a hole on the corner of the EMU housing! Turns out the aluminium housing of the EMU is floating! Neither grounded nor as best I can determine isolated! Luckily the mounting bracket of the relay is isolated, but it means a longer wire run from the relay coil to ground at the battery negative terminal.

So with this selected, the tedious and trying task of getting a guide rod through the bulkhead rubber gasket was next. The rod in question being a 1.5mm stainless steel antenna rod. Thin and flexible to do the job, but none the less a real pain when single manned. Without an assistant, it was a case of push a few centimeters, climb out the footwell, into the engine bay, look but mostly feel for the end of the rod, and repeat, until such a time as I could finally grip and pull the rod far enough to attach the wire, without damaging anything else close by - cables, hoses etc! With the single 5A wire (blue) taped to the end of the rod, and an ample estimated length payed out from the spool, came the nerve wracking task of pulling the rod back though the bulkhead into the footwell beside the fusebox, hopefully without losing the end! Well, it took considerably more force than expected to get the bulge of the joint through!

So now, I have the relay fitted in place, hand tight, the control wire fed through, crimped and connected to one side of the relay coil. The ground connection wire is crimped and connected to the other side of the relay coil, has the eyelet crimp attached, but it tied up and taped ready to be attached to the battery negative terminal later. The fusebox end of the control wire is unterminated, and the positive high current connections are currently a loop of 30A wire crimped and attached to both of the relay contacts! This is because A - I dont have the bloody 'add-a-circuit' fuse module to complete the control connection, and B - Ive run out of bloody butt-joint crimps to complete the high current wiring with!

And so the circuit will stay in this state, as will the passenger side footwell and seat, which are littered with tubs of crimps, fuses, wire, tools etc, as well as the temporarily removed, but still full, glovebox itself, until such a time as I can get to my automotive parts supplier. Which could be hours, might be days.

And all this came about because im stuck in the house awaiting a delivery, and I also had a blown brake light to replace!